Gantry Machining Center: A Comprehensive Guide

Anderson

- 0

Are you looking for a reliable and efficient machining solution? Look no further than the gantry machining center. This advanced technology offers unparalleled precision and productivity, making it an ideal choice for various industrial applications.

The Advantages of Gantry Machining Center

The gantry machining center is known for its exceptional stability and rigidity, ensuring superior accuracy in every operation. Its large working area allows for the processing of larger workpieces with ease. Additionally, the gantry design provides excellent accessibility to all sides of the workpiece, enabling efficient multi-sided machining.

Furthermore, this cutting-edge machine offers high-speed spindle options that can significantly reduce cycle times while maintaining optimal surface finish quality. With its advanced control system and intelligent tool management capabilities, the gantry machining center ensures seamless operation and maximizes production efficiency.

Finding the Best Vertical Machining Center

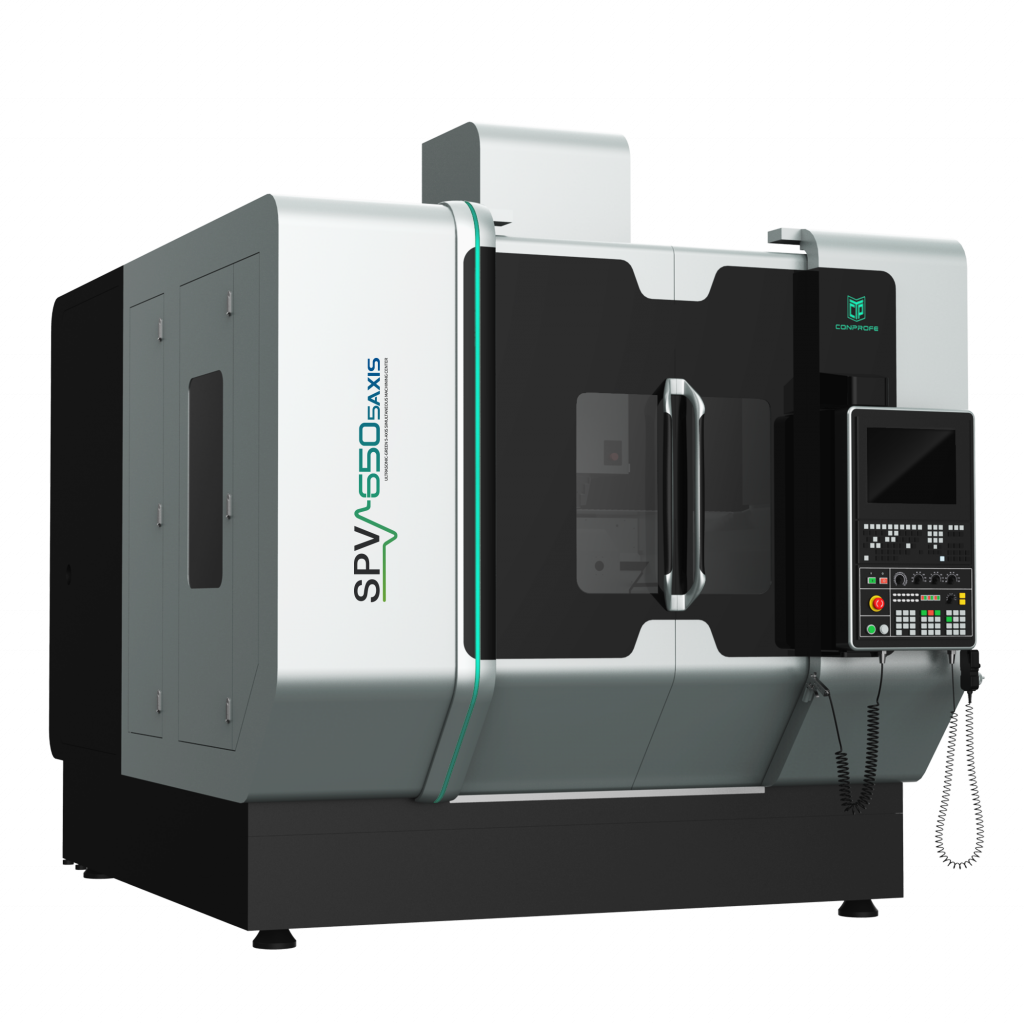

When selecting a vertical machining center (VMC), several factors need to be considered to ensure you choose the best one for your specific needs. Firstly, evaluate the machine’s structural design and construction materials to guarantee stability during heavy-duty operations.

In addition to structural integrity, pay attention to spindle speed range and power capacity as they directly impact cutting performance. The VMC should also provide flexible tooling options along with easy-to-use software interfaces that enhance programming efficiency.

Moreover, consider features such as automatic tool changers, coolant systems, chip evacuation mechanisms, and overall maintenance requirements when comparing different VMC models. By carefully assessing these aspects based on your application requirements and budget constraints, you can find a vertical machining center that meets your expectations.

An Introduction to Rotary Ultrasonic Machining

Rotary ultrasonic machining (RUM) is a cutting-edge technique that combines the advantages of ultrasonic machining and diamond grinding. This process utilizes high-frequency vibrations and abrasive slurry to remove material from the workpiece, resulting in precise and efficient machining.

RUM offers several benefits, including reduced tool wear, improved surface finish quality, and enhanced dimensional accuracy. It is particularly suitable for hard and brittle materials such as ceramics, glass, or composites that are challenging to machine using conventional methods.Click rotary ultrasonic machining .

By leveraging the power of ultrasonic energy combined with rotational motion, RUM enables faster material removal rates while minimizing thermal damage to the workpiece. This innovative technology has revolutionized various industries by providing an effective solution for intricate part manufacturing.

Conclusion

The gantry machining center stands out as a versatile and reliable solution for precision machining needs. Its exceptional stability, large working area, and advanced control system make it an ideal choice for various industrial applications. Additionally, considering factors like structural design and construction materials can help you find the best vertical machining center tailored to your specific requirements. Lastly, exploring innovative techniques like rotary ultrasonic machining expands possibilities in achieving superior results when working with hard or brittle materials.